The market for metallic stearates is approximated to be USD 3.7 billion in 2023, and it is projected to reach USD 4.9 billion by 2028 at a CAGR of 5.4%. Metallic stearates are metal salts of fatty acids, primarily stearic acid, that are used as additives in various industries such as plastics, rubber, construction, and pharmaceuticals. The primary function of metallic stearates is to act as lubricants, release agents, and stabilizers, improving the properties of the final product.

The market of metallic stearates has been segmented based on the type, i.e. zinc stearates, calcium stearates, magnesium stearates, aluminum stearates, and others. Steroids

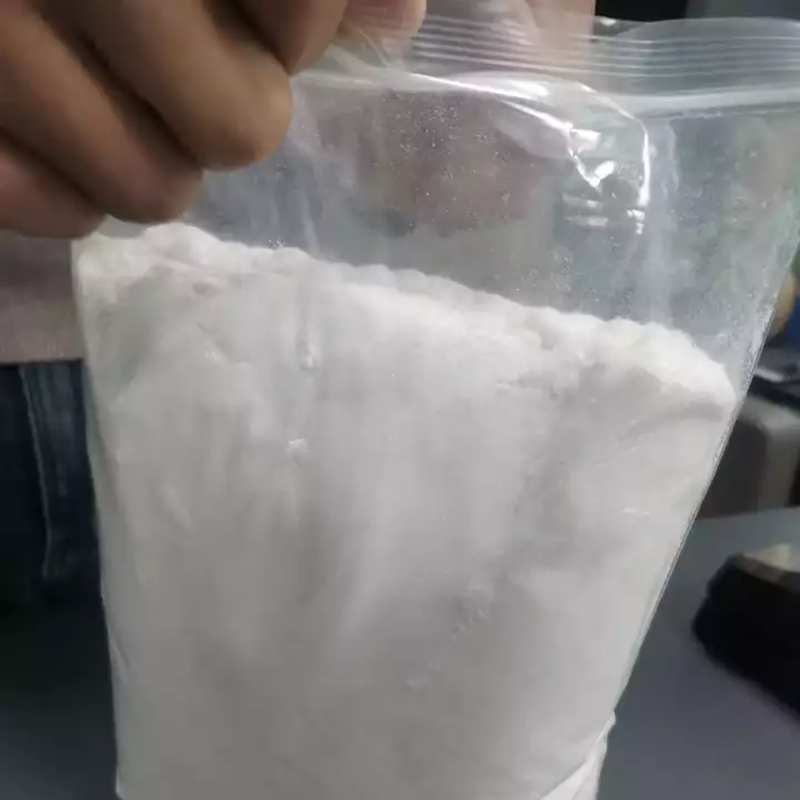

Zinc stearate has the largest market share in metallic stearates market in 2022. Zinc stearate is a white, powdery substance that is widely used as a release agent in the production of rubber and polyurethane foam.

It is also used as a lubricant and stabilizer in plastics. In rubber manufacturing, it is added to the compound to prevent it from sticking to the molds during the vulcanization process.

In polyurethane foam production, it acts as a blowing agent and releases the foam from the molds. Zinc stearate is also added to plastics to improve their flow properties and to prevent them from sticking to processing equipment.

Furthermore, calcium stearate is a white, waxy substance that is commonly used as a lubricant and release agent in the production of plastics, rubber, and paper. In plastic manufacturing, it is added to PVC to improve its processing properties and to prevent it from sticking to processing equipment.

In rubber production, it is used as a mold release agent and to prevent the rubber from sticking to the molds during curing. In paper manufacturing, it is used as a lubricant to prevent the fibers from sticking to processing equipment.

Moreover, magnesium stearate is a white, powdery substance that is widely used as a lubricant and flow agent in the production of pharmaceuticals, cosmetics, and food. It is added to tablets and capsules to improve their flow properties and to prevent them from sticking to the processing equipment.

In cosmetics, it is added to creams and lotions to improve their texture and consistency. In food manufacturing, it is used as a flow agent to prevent ingredients from clumping together.

The metallic stearates market is segmented based on end-use industries. Metallic stearates can be used in polymer & rubber, pharmaceuticals & cosmetics, building & construction, paints & coatings, and in other end-use industries.

Pharmaceuticals & cosmetics and food segment is projected to witness highest cagr during the forecast period. In pharmaceuticals & cosmetics industry, metallic stearates such as magnesium stearate and calcium stearate are widely used as excipients to improve the physical and chemical properties of medications and cosmetic products.

In the pharmaceutical industry, magnesium stearate is used as a lubricant to prevent ingredients from sticking to tablet presses and allows for easy ejection of tablets, while calcium stearate is used as a flow agent in the production of powders. In cosmetics, metallic stearates are used as bulking agents, thickeners, and anti-caking agents to improve the texture, stability, and performance of cosmetic products.

Zinc stearate is also used as a matting agent in cosmetic powders to create a matte finish. On the other side, in polymer & rubber industry, metallic stearates such as zinc stearate and calcium stearate, are widely used as release agents and lubricants.

Zinc stearate is particularly effective as a release agent in the production of rubber and polyurethane foam, helping to prevent these materials from sticking to molds during production. Calcium stearate, on the other hand, is often used as a lubricant and release agent in the production of plastics, rubber, and paper.

Metallic stearates also help to improve the processing characteristics of rubber and polymer materials, such as their flow and viscosity, and can act as stabilizers to prevent degradation during processing and storage.

The metallic stearates market is studied in five regions, namely, Asia Pacific, Europe, North America, the Middle East & Africa, and South America. Asia Pacific is the fastest-growing market of metallic stearates globally.

This is attributed to many factors such as the region has a rapidly expanding industrial sector, particularly in the areas of plastics, rubber, and construction, which are the major end-use industries for metallic stearates. Additionally, the region has a large and growing population, which is driving demand for consumer goods, including cosmetics and pharmaceuticals, which are other key end-use industries for metallic stearates.

Zinc Calcium Stearate Moreover, many of the major metallic stearate manufacturers have operations in the region, attracted by the region's lower labor costs and favorable regulatory environment. Finally, the region's increasing urbanization and infrastructure development are driving demand for coatings, adhesives, and lubricants, which are other key applications for metallic stearates.